- Home

- Service: Risk And Safety

Risk And Safety

Following are the services listed in Risk And Safety

Overview

Process safety is part of safety management and focuses on the concerns of major hazards impacting, safety, environmental damage and business losses. The goal of process safety management is to develop plant systems and procedures to prevent unwanted releases that may ignite and cause toxic impacts, local fires or explosions.

HAZID

HAZID (Hazard Identification) is a qualitative technique for the early identification of potential hazards and threats affecting people, the environment, assets or reputation.

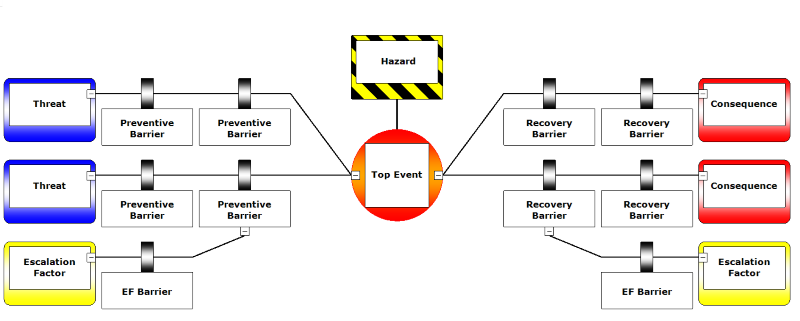

Bow Tie

A 'bowtie' is a diagram that visualizes the risk you are dealing with in just one, easy to understand the picture. The diagram is shaped like a bow-tie, creating a clear differentiation between proactive and reactive risk management.

HAZOP

A Hazard and Operability study (HAZOP) is a structured and systematic examination of a planned or existing process or operation in order to identify and evaluate problems that may represent risks to personnel or equipment, or prevent efficient operation; it is carried out by a suitably experienced multi-disciplinary team (HAZOP team) during a set of meetings.

SIL

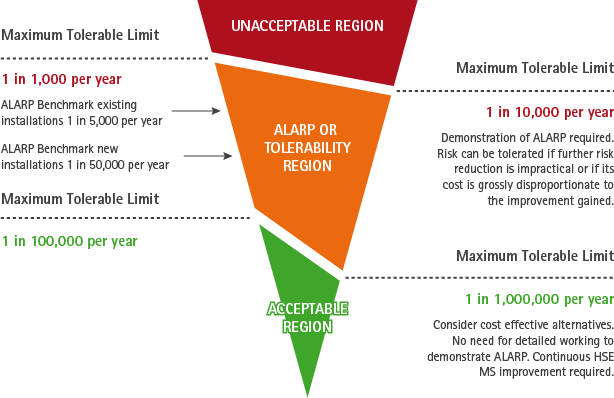

Safety Integrity Level (SIL) studies are a formal method of assessing the probability that a functional safety system will fail when it is needed. The assessed probability of a safety system failing acts as a measurement of the level of risk reduction that the system provides.

A safety integrity level refers to the reliability of an entire safety system, not to the individual risk reduction measures that comprise them.

Safety Integrity Levels are defined according to an international standard described by the International Electrotechnical Commission (IEC).

HIRA

Hazard Identification and Risk Analysis (HIRA) is a collective term that encompasses all activities involved in identifying hazards and evaluating risk at facilities, throughout their life cycle, to make certain that risks to employees, the public, or the environment are consistently controlled within the organization’s risk tolerance.

Consequence Analysis & QRA

Consequence Analysis is the process of examining the possible effects of a planned activity, for example, the possible risks to the environment that may be caused by building work:

Quantitative Risk Analysis is proven as a valuable management tool in assessing the overall safety performance of a Chemical Process Industry. It is a formal and systematic risk analysis approach to quantifying the risks associated with the operation of an engineering process. A QRA is an essential tool to support the understanding of exposure of risk to employees, the environment, company assets and its reputation. A QRA also helps to make cost effective decisions and manages the risks for the entire asset lifecycle.

Fire Gas Detector Mapping

Hydrocarbon detector mapping using Dispersion Modelling Software is a scientific way of locating the detectors adopted by Major process , chemical , Oil & gas Companies. It helps in identifying the leakage at an early stage, and acts as an optimization tool to fix up the quantity of the detector. With the installation of Hydrocarbon Gas & flame Detection System, the risk is considerably reduced to As Low as Reasonably Practicable (ALARP) level.

Loss Prevention & Environment Engineering

- Preparation of hazardous area classification and layouts

- Passive fire protection design and layouts

- Noise mapping study by using sound plan software

- Review of EIA study ,Dispersion analysis study for plant emission sources

- EER study , safety sign & escape route layouts